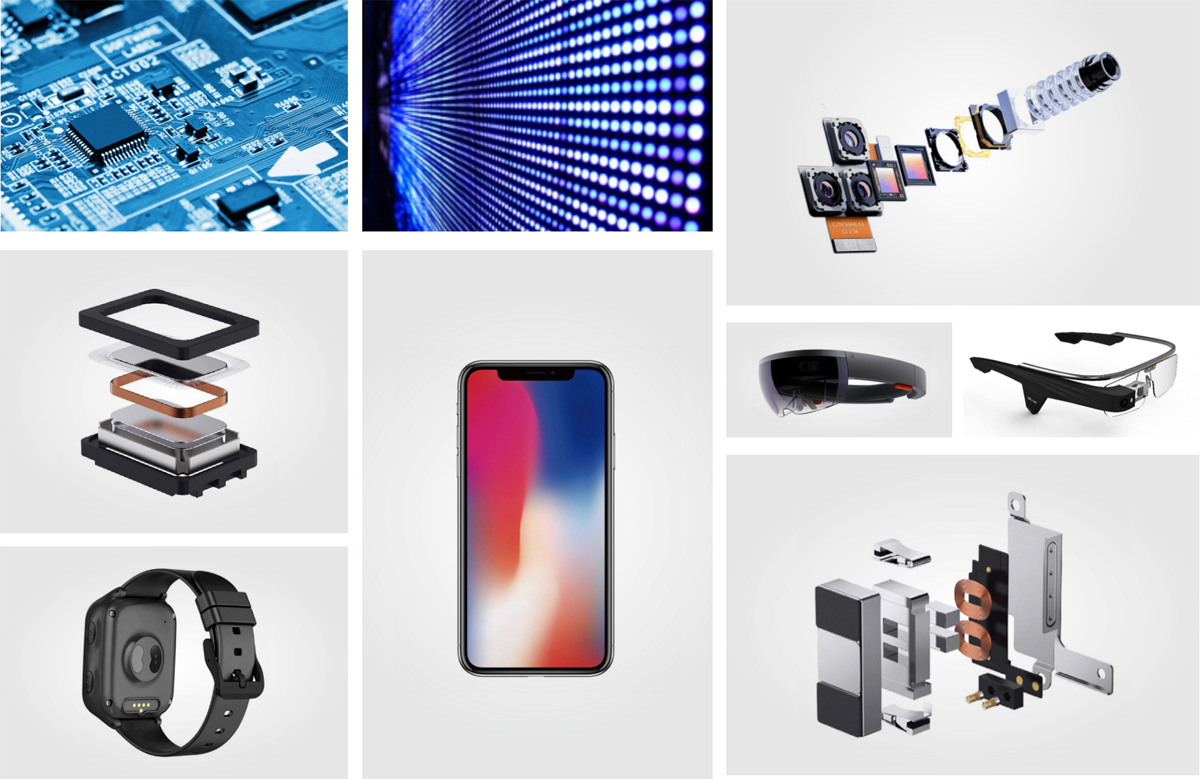

Mainly used in the field of consumer precision electronics, including processes such as dust-catching gluing, prism gluing, Holder Bond, Lens shading gluing, enameled wire welding for VCM and solder joint protection gluing in the CCM field, Tuffy gluing in the screen display field, MiniLED Chip Coating, Underfill in the SMT field, Component Coating, 3D mobile phone middle bezel dispensing in the FATP field and VR/AR middle bezel dispensing

FATP: Smartphone, Smart Watch, XR/VR

SMT: PCB Component, FPC Component

Optical Component: CCM, LENS

Screen Display: OLED、LCM、MiniLED、TFT-LCD、Micro-LED

Precision Motor: Linear Motor, Voice Coil Motor

Discrete Component: MEMS Microphone, MEMS Barometer, Optical Communication Device

CCM: Dust-catch Glue, Lens Glue, Holder Bond, Lens Light-blocking Adhesive

VCM: Enamel Wire Soldering & Solder Joint Protection Adhesive

Screen Display: Tuffy Glue、MiniLED Chip Coating

SMT: Chip Underfill、Component Coating

FATP: 3D Phone Mid-frame Dispensing、VR/AR Mid-frame Dispensing

In the era of ever-smaller, higher-performance, and longer-lasting smartphones, ultrathin laptops, and wearable devices, the miniaturization and integration of internal components have become key trends. Advanced materials such as ceramics, silicon carbide, diamond, carbon fiber composites, and titanium alloys—characterized by high strength, hardness, and brittleness—are widely applied, placing stringent demands on machining precision and quality. Water jet guided laser processing technology, with its unique composite capabilities, effectively suppresses micro-cracks, thermal damage, and edge chipping, enabling breakthroughs in precision manufacturing for consumer electronics while ensuring the reliability and stability of high-performance components.

Typical Applications |

Typical Materials |

|---|---|

|

|

Carbon-based Diamond

Carbon-based Diamond

Copper-based Diamond

Copper-based Diamond

Boron Nitride

Boron Nitride

Alumina Ceramic

Alumina Ceramic